Mention 3D printing and someone is likely to think about small plastic things such as customized Lego bricks or miniature dinosaurs.

3D printing is something entirely different at the University of Alaska Fairbanks Geophysical Institute, which operates the university system’s only 3D metal printer. UAF purchased the printer in mid-2020, but it was not ready for use until this year.

With it, the Geophysical Institute can make specialized research tools and components for scientists and serve the university in other ways, saving time and money. Intricate parts can be designed and produced onsite instead of being outsourced.

“To be able to do metal printing greatly expands what we can do,” said Greg Shipman, manager of the Geophysical Institute Machine Shop. “One of the big advantages to 3D printing is you can accomplish geometry that would be next to impossible to do with machinery.”

The process is similar to printing with plastic, with just a few added steps. The machine shop has several traditional and high-temperature 3D printers of varying sizes, all of which use thermoplastic filaments.

Creating something with a 3D metal printer involves several processes, depending on the type of printing technology used. The Geophysical Institute’s metal printer uses a system called “fused deposition,” a technology that is less costly than some other methods of 3D metal fabrication.

Fused deposition starts with the filament, which consists of nylon merged with metal. It could, for example, be stainless steel, copper, tool steel or Inconel, a steel that can withstand temperatures of up to 2,200 degrees Fahrenheit.

The printer, as with other 3D printers, extrudes layer upon layer of filament as directed by its computer. It knows precisely how much nylon and metal the finished object requires.

The next steps unveil the true creation.

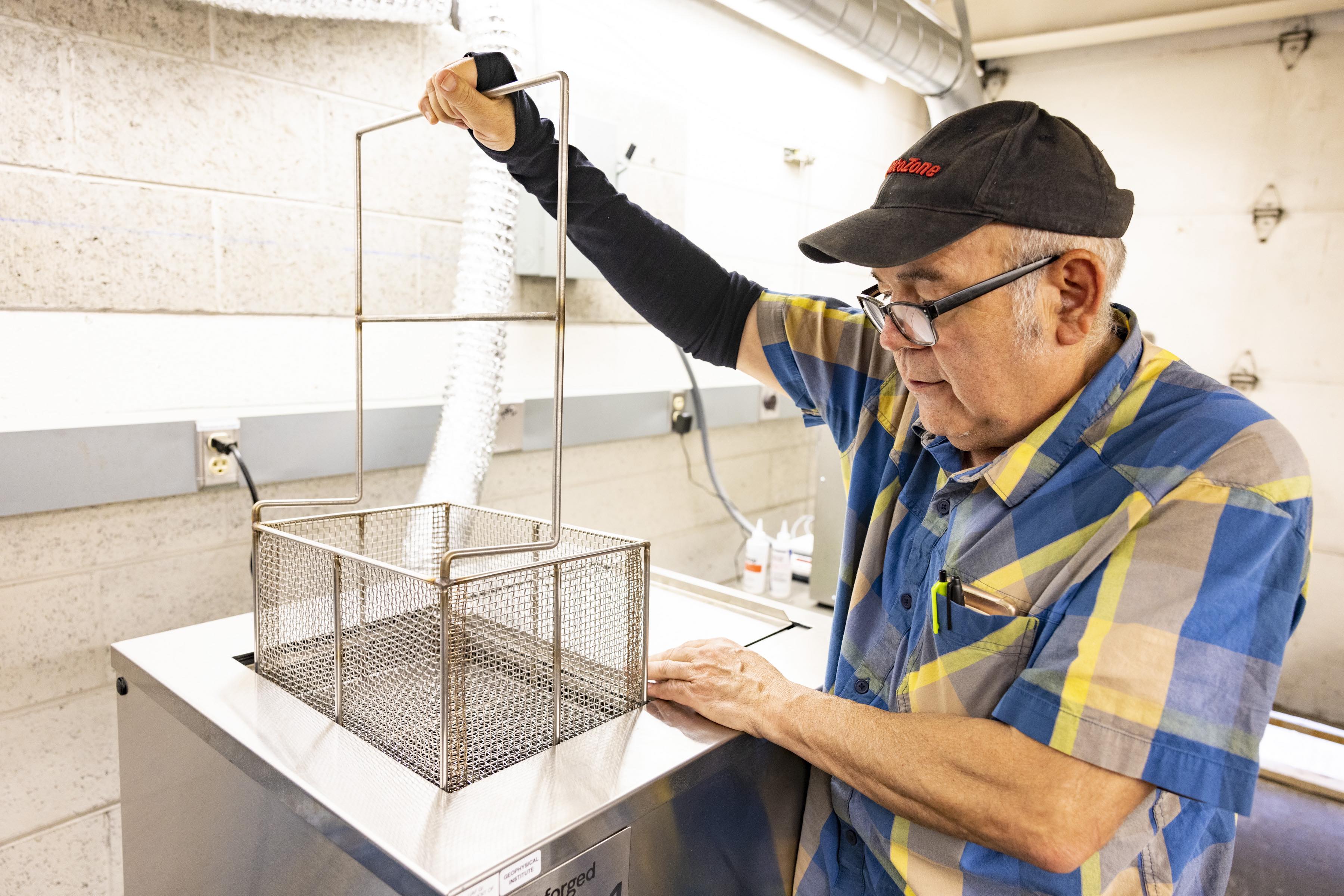

The item that comes out of the printer is considered to be in a “green state.” It goes to a wash station to strip away the nylon layer, revealing the precisely measured item.

The final step is the furnace.

“The computer controls the furnace,” Shipman said. “And what it's doing is fusing those particles together and maintaining that same degree of accuracy.”

Technology continues to transform the institute’s Machine Shop.

“We’re a machine shop, but we’ve got computers all over the place,” Shipman said. “One side of our shop is for manual machines. And the other side is for computer-controlled machines.

“We’re in a new phase. What we’d like to do is to just make others aware of the capabilities of this 3D metal printer — and not just this machine but all our machines,” he said.

The new $139,000 printer, manufactured by the Markforged company of Massachusetts, is available to serve other UAF units through the Geophysical Institute Machine Shop. UAF Vice Chancellor for Research Nettie La Belle-Hamer purchased the printer. The Geophysical Institute paid for the printer’s installation and the necessary renovation on the Elvey Building’s ground floor.

“We are pleased to have this new 3D metal printer at the Geophysical Institute and available to serve UAF,” said Jami Warrick, the Geophysical Institute’s operations manager. “Its purchase demonstrates the university’s continued commitment to research in the Arctic.”